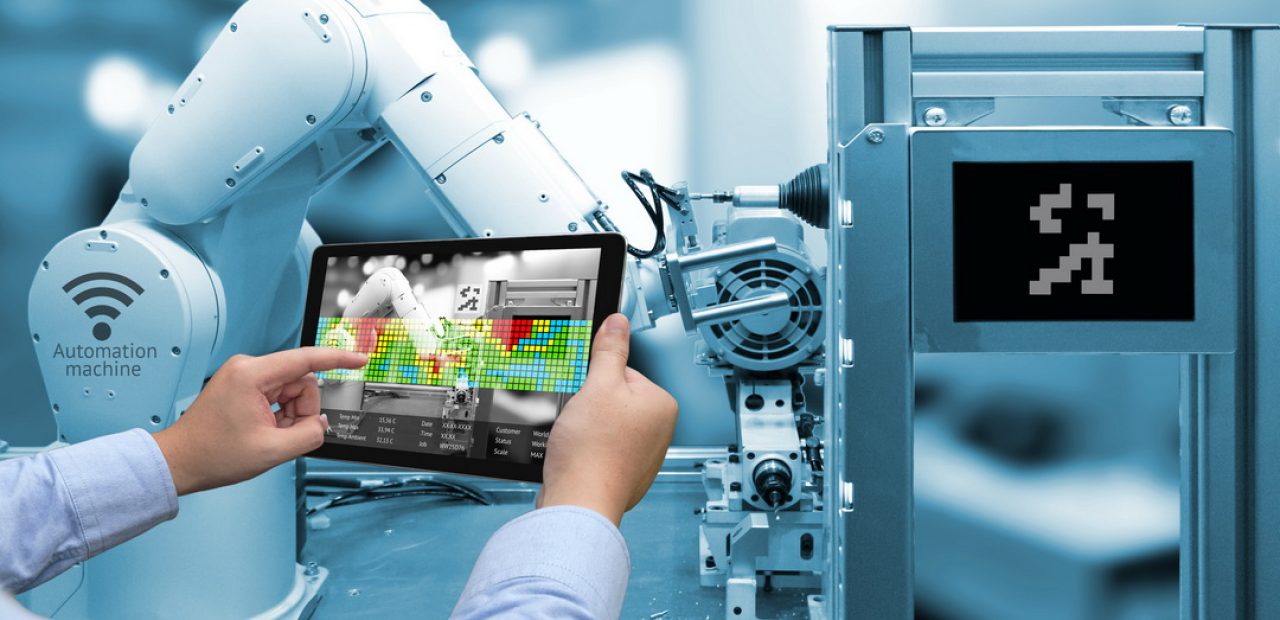

Conventional manufacturing on the verge of intelligence

Digital twins are the key to achieving smart factories. They will open the door to the manufacturing industry’s cyber-physical future.

Digital twins are cyber clones of physical things. Their use in product design and planning is big news at the moment, and using them to plan entire factories is potentially the next major step toward smart manufacturing.

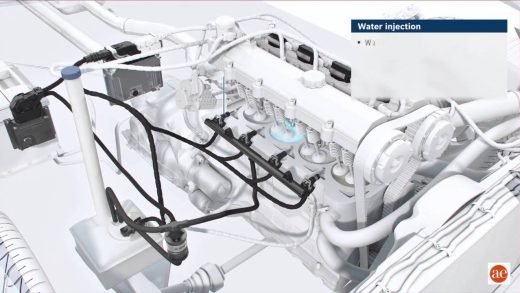

Digital twins are already revolutionizing the development of smart products. Based on physics data, they digitally model forms, functions and chemical and physical processes. This dramatically reduces the cost of developing prototypes, because faults can be weeded out long before things get expensively physical. Once the product has taken on physical form, it feeds real-world data back to its digital twin throughout its entire lifecycle. In this way, digital twinning can be used to optimize processes, reduce costs and shorten time to market. An impressive example of this is the shipping industry, where General Electric (GE) is charting new waters by fitting cruise liners with sensors that feed data to digital twins. The idea is that the twins will reduce ship down-time by constantly monitoring and analyzing wear data.

Virtual commissioning of smart factories

The next chapter in the smart factory story could well revolve around designing digital twins of entire production plants. With digital twins, plants can be virtually tested in 3D before being physically commissioned into service. Faults and malfunctions can thus be remedied before the hardware is delivered, thereby saving time and money. And once the plant is operational, it is possible to continuously optimize processes by feeding real data back to the digital twin. For example, the Austrian vehicle engineering and contract manufacturing firm Magna Steyr is currently upgrading its production facilities . As well as collaborative robots, the plans call for a virtual model of the entire factory. Meanwhile, the German packaging machinery manufacturer Optima already has such a digital twin in use. Its new production line conveyor system is supported by a digital model that simulates re-configurations and product flows.

The future of digital factory twins is, of course, closely aligned with the future of big data for the simple reason that virtual models of entire production systems and factories necessitate the processing and storage of truly colossal amounts of data. Perhaps in the not-too-distant future, digital representations of factories will operate in real-time alongside their physical counterparts in such a way that on-screen changes to the virtual factory will automatically initiate changes to the real factory.

More about these new concepts and technologies you can find out by visiting Hannover Messe 2017.Those who wish to participate as visitors can obtain free tickets by visiting this link .

For details on participation in Hannover Messe, contact the Deutsche Messe reptresentative for Romania and Moldova:

Luminiţa Constantin

- Tel: +40 21 207 91 64;

- E-mail: [email protected]

Source: Hannover Messe

Photo/video source: Hannover Messe

Recent Comments