Conventional manufacturing on the verge of intelligence

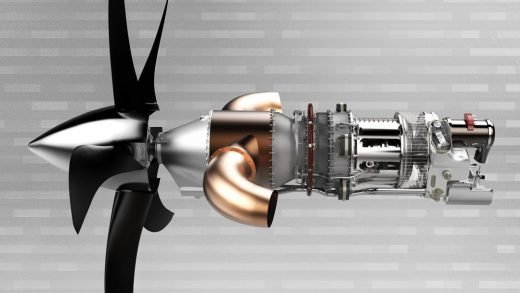

Digital twins are the key to achieving smart factories. They will open the door to the manufacturing industry’s cyber-physical future.

Digital twins are cyber clones of physical things. Their use in product design and planning is big news at the moment, and using them to plan entire factories is potentially the next major step toward smart manufacturing.

Recent Comments