Bosch is using Industry 4.0 to increase its competitiveness

More than 100 projects worldwide:

- Data mining and RFID increase productivity in ABS/ESP braking-system manufacturing by one-quarter

- Increase of productivity by 10 percent, reduction of storage in production by nearly one-third

- Increased competitiveness and transparent processes through Industry 4.0 in the production units from Cluj and Blaj

Berlin and Stuttgart – Bosch is making its manufacturing connected, with more than 100 projects already successfully running worldwide. Among other benefits, this increases the availability of its machinery – and hence also its productivity and competitiveness. Here are a few selected examples:

One production line, 200 different hydraulic modules

On its multi-product assembly line in Homburg, Germany, Bosch can manufacture 200 different hydraulic modules from more than 2,000 different components. Thanks to connectivity, these components are automatically ordered in time. The modules control the work and driving hydraulics in trucks or tractors, which help do things such as incline loading surfaces or lift a plow. The produc- tion line’s nine stations are connected by a smart network.

Thanks to an RFID chip attached to the workplace, the stations know how the finished product has to be assembled and what steps are necessary. This facilitates efficient production, even for small batch sizes. That flexibility is important, since some modules are requested more often than others. What is more, Bosch can produce different types of module simultaneously on the multi-product line. This cuts tooling times on machinery, which increases productivity. The work plans required for assembling the hydraulics components are automatically called up and shown on the monitors as a photo or video. The display is customized to each associate’s level of training, and shown in their native language. The aim is to offer associates the best possible support in their work. This is an example of how Bosch is successfully putting multiple core elements of Industry 4.0 into practice: distributed intelligence, rapid connec- tivity, contextualization in real time, and autonomous behavior. Details: http://bit.ly/1QqPUiB.

Industry 4.0 boosts productivity in ABS/ESP braking-system manufacturing

Award-winning success: in less than one year, Bosch improved its productivity in the manufacture of ABS/ESP braking systems by nearly one-quarter by deploying Industry 4.0 solutions throughout its international manufacturing network. In recognition of this achievement, the Blaichach plant – which spearheaded the initiative – received the prestigious Industry 4.0 Award in 2015. One reason for this productivity increase is that Bosch collects data from the thousands of sensors that are installed along the plant’s production lines. Sensors record the move- ment of cylinders, the cycle times of grippers, and the temperature and pressure levels in the manufac- turing process. This wealth of information is entered into massive databases, with a clear structure. And thanks to RFID (radio frequency identification) technology, Blaichach can also digitally map its internal flows of goods. The result is a computer-generated virtual repre- sentation, or “digital twin,” of the actual factory. This digital representation facilitates transparency across the entire value stream. And in turn, this transparency makes many more I4.0 solutions possible.

One of these solutions is applied in machinery maintenance: software analyzes machinery performance to spot deviations from the target state and indicate in good time when maintenance is necessary. The system helps associates detect and deal with errors by offering them instructions on how to carry out these repairs. On their tablets, for instance, associates can call up videos showing them how to replace parts. If they encounter a problem they cannot solve immediately, they can use a wireless video link to speak with experts who then assist in solving the problem remotely. All this reduces unplanned downtimes as well as increasing productivity and hence also competitiveness.

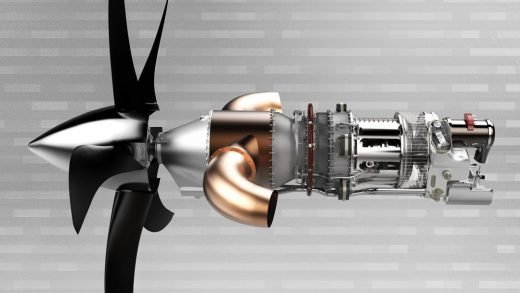

Predictive maintenance of machine tools

One of the items Bosch manufactures at its plants in Stuttgart-Feuerbach (Germany) and Jihlava (Czech Republic) is high-pressure pumps for injection systems. Part of the manufacturing process for the aluminum housing involves precise drilling of holes and milling of other parts. Large machine tools are deployed in the process, whose motorized drive units are referred to as “spindles.” Each spindle weighs some 50-70 kilograms and spins at a rate of 30,000 to 40,000 rpm. Sensors record vibrations in the operation of these spindles, and software stores and evaluates the data.

Whenever the system registers that the intensity of vibrations exceeds a set limit, it sends a signal to the service associate in charge. The technician can then decide if and when to replace the spindle. Maintenance becomes easier to plan, machine availability improves, and productivity rises. Continuous monitoring of machine parts such as these spindles is also referred to as “condition monitoring.” Planned servicing is called “predictive maintenance.”

Radio signals create transparency in the flow of goods

In many of Bosch’s more than 250 plants worldwide, the company has equipped plastic crates for the internal transport of parts and finished products with RFID (radio frequency identification) tags. RFID readers are positioned at all the doors to the manufacturing shops. When a transport cart goes from one shop to another, the reader registers its tag automatically and without any need for physical contact.

The result is a digital map of the flows of goods in that particular plant. At any time, the company can determine when parts will most likely arrive on the production line, when and how many finished products have to be packaged, where a specific part is located, and what the inventory levels are. The system also knows how many packaging boxes are required and can reorder these as needed.

RFID technology ensures transparency in the flow of goods, as well as reducing manual effort and keeping inventory levels low. It simultaneously increases reaction speed and productivity. This is how Bosch achieves leaner logistics processes. Thanks to its use of RFID, Bosch was able to boost productivity in its Homburg plant’s intralogistics by 10 percent, and reduce storage in production by nearly one-third.

Industry 4.0 in the Bosch production units in Romania

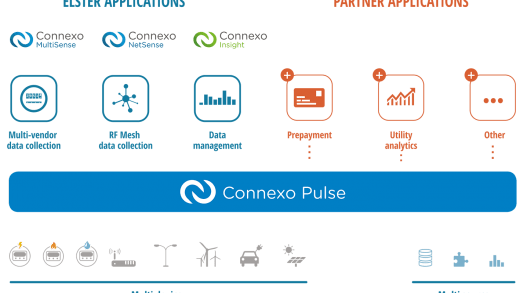

The Bosch plant uses the newest equipment and IT infrastructure for production in form of the MES (Manufacturing Execution System), that connects and controls all work centers in order to provide complete traceability of the products, starting from the first production step in the SMT (Surface Mounting Technology) area until the final step, packaging area, including automatic booking to the ERP System (SAP).

To be even faster in implementation of additional functions, the automotive plant in Cluj carries over developments from other Bosch locations. For example, machines are equipped with NFC (Near Field Communication) tags. By scanning them via standard smart phones, the service staff can immediately check spare parts availability, access all machine documentation and much more. The supply of production materials to all workstations is controlled by computer readable material tags. Logistics monitoring can be easily done by recognizing remote readings of RFID (Radio-frequency identification) tags.

Cluj-Napoca is famous for its IT competence in Europe. Therefore, Bosch integrates the competence and skills of local companies into projects like Industry 4.0 the NGPro Operations WEBreporter or the TQS (Training-Qualification-Service).

The production unit from Blaj achieved interconnectivity for automotive production lines through Bosch Rexroth solutions. The first step was to connect the stations from the automated and semi-automated production lines to a master industrial computer (PLC) that gathers all the relevant production information. In the second step the company worked on a server solution for data storage and developed an interface for information processing (for example ANDON application) which sends the production information to the relevant persons in real time.

The raw material is monitored through the radio frequency identification technology (RFID) and afterwards the data is processed by the master industrial computer. In this way, Bosch is generating, storing and processing all the data from the production lines. This leads to more transparent processes and an easy approach to the “Zero Failure” Bosch Strategy.

The Bosch Group is present in Romania for over 20 years and employs more around 3,000 associates in four entities (as of December 31, 2015). In 2014, Bosch generated sales of 210 million Euros*. Besides its research & development center and the production unit for automotive technology in Cluj, Bosch also operates a production unit for linear motion technology and one for automotive technology in Blaj and a center for business process outsourcing solutions in Timisoara. In Bucharest, Bosch runs a distribution company for power tools and accessories, thermotechnology, security systems and products for the automotive industry. In addition, in the capital there is a branch of BSH Hausgeräte GmbH, active in the market of household appliance.

Source: T&T - Tehnică și Tehnologie

Photo/video source: T&T - Tehnică și Tehnologie

Recent Comments