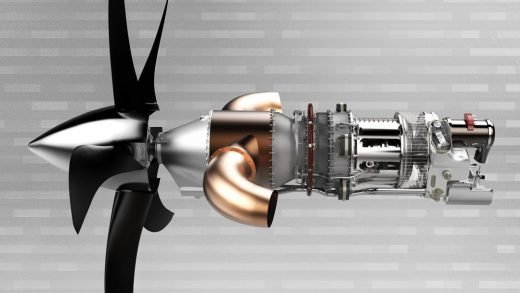

Materials like aluminum and carbon are making our cars, rockets and ships lighter and lighter. However, perfect materials alone cannot guarantee the best possible results.

The lightweight construction trend in the industrial sector continues unabated. By 2030, the annual turnover with lightweight components made of high-tensile steel, aluminum and carbon-fiber-reinforced plastic is set to explode from roughly 70 to over 300 billion Euros . By far the most important market for this is the transport sector , followed by the aerospace and shipping industries. The legally-mandated CO2 reduction for automobiles by 2020 is one reason why the lightweight construction trend remains so dynamic. That makes electric drives – and lightweight construction – increasingly important for the automotive industry. Batteries are heavy, so manufacturers have to find other areas where they can save weight to improve the range of electric vehicles. However, lightweight construction is catching on more and more in other transport and industrial sectors thanks to the potential efficiency improvements and environmental benefits.

Recent Comments