Robot or cobot: The five key differences

CCobots are on the rise. How do they differ from conventional industrial robots?

The concept for cobots (collaborative robots) was born in 1995 as part of a research project spearheaded by the General Motors Foundation. The idea was to make robots so safe that they could literally work hand in hand with people. Now, twenty years later, cobots have found a place on many factory floors – and also in public awareness. And yet many don’t really understand how cobots are different from robots.

- Partnering in human-machine teams

Classic industry robots are powerhouses that carry out their work following a fixed program, without regard for the people working around them. Accidents are prevented using fences and cages.

Cobots, however, are specifically designed to work together with people, not just for them. Instead of being caged, they work in a cooperative environment and assist with complex tasks that cannot be fully automated. For example, they can hand components to human coworkers, who execute the more precise assembly or quality control tasks.

- Relief from risky activities

Cobots fulfill tasks that could be risky for people, such as safely transporting sharp, pointed or hot work pieces, or dangerous bolting work. This results in fewer accidents, and leaves technicians to focus on less arduous aspects of production.

- “Smart” and safe behavior

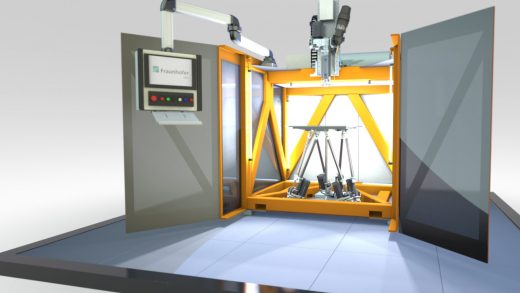

Cobots are designed to work seamlessly together with their human colleagues. They immobilize at the slightest touch thanks to sophisticated sensors, to prevent any danger to nearby people. Closed areas and safety fencing are no longer needed.

- Flexible and teachable

Cobots are very easy to program. Unlike traditional industrial robots, which require specialized programming skills, some cobot models even learn independently. For example, from a technician performing a movement with the robot arm, which the cobot can then automatically reproduce. Other systems can be given work instructions without coding, using a graphic user interface. Employees can thus flexibly reprogram cobots and use them for a variety of tasks.

- Usable anywhere

Not only are cobots easy to reprogram, they are also relatively easy to move and utilize at other points on the production chain. Most cobots can be mounted on any surface – horizontal, vertical, on the ceiling. And they are often light enough to be carried by just one person.

Source: Hannover Messe

Photo/video source: Shutterstock

Recent Comments