Machine learning: artificial intelligence in Industry 4.0

Machine learning enables predictions to be made based on large amounts of data. This branch of artificial intelligence is built upon pattern recognition and has the ability to independently draw knowledge from experience. For this reason, the technology has found its place in industrial processes.

Artificial intelligence is no longer a vision for the future. Today, large data centers and enormous storage capacities make things possible that were believed for years to be distant concepts. Two branches of artificial intelligence, machine learning and deep learning, use the possibilities of big data to optimize processes, find new solutions, and gain new insights.

Algorithms form the basis

From small and medium-sized companies to large international corporations, every organization accumulates data that it can make use of. With software, this data is consolidated and evaluated to make predictions. Machine learning recognizes characteristics and relationships and uses algorithms to derive generalizations from them.

Big data for optimizing processes

With the help of properly analyzed customer, log, and sensor data, new solutions can be found and processes can be made more efficient, for example. In addition to masses of data, this requires an IT infrastructure that is adjusted to artificial intelligence processes and machine learning workloads. The exact tasks of the machine learning systems are clearly defined: to recognize patterns and draw conclusions from them. The findings can then be further utilized.

Current applications of machine learning

At present, the most commonly used learning method is image recognition. Other uses include digital assistants or intelligent bots, face recognition, speech recognition and speech processing, automated translation and transcription, text and video analysis, and autonomous driving.

Artificial intelligence in Industry 4.0

In a smart factory, production processes are connected – machines, interfaces, and components communicate with one another. Large amounts of data can be collected to optimize the manufacturing process. Big data supports process optimization by using image analysis and image recognition, for example.

Digital monitoring and control

In production facilities, intelligent systems identify objects on conveyor belts and are able to automatically sort them. These types of systems are also used in quality control: They recognize product flaws, such as whether it is the wrong color.

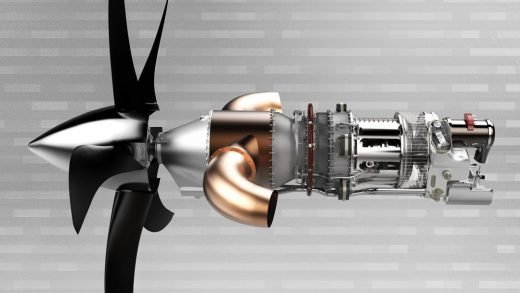

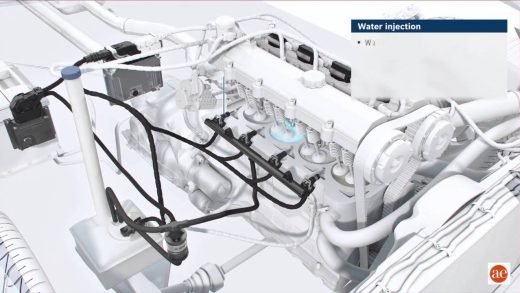

Artificial intelligence and predictive maintenance

Companies today use machine learning in maintenance and support services. By means of sensors, artificial intelligence helps capture the energy consumption of individual machines, analyze maintenance cycles, and then optimize them in the following stage. Operating data indicates when a part must be replaced or where there is likely to be a defect. As the amount of data increases, the system becomes better at optimizing itself and making more accurate predictions.

Artificial intelligence expected to drive growth

According to experts, companies that use machine learning processes increase their economic performance. The biggest gains are expected in the IT and finance sectors, telecommunications, and the manufacturing industry.

Source: Hannover Messe

Photo/video source: Photo by Christopher Burns on Unsplash

Recent Comments