Researchers create a 3D-printed vehicle that can power a 3D-printed home (and vice versa)

Dubbed AMIE (Additive Manufacturing Integrated Energy), the innovative platform features special technology that allows a bi-directional flow of energy between a dwelling and a vehicle (Credit: ORNL)

A research team from the Department of Energy’s Oak Ridge National Laboratory (ONRL) has created a new model for how we can connect the way we power our homes and vehicles. Dubbed AMIE (Additive Manufacturing Integrated Energy), the platform features special technology that allows a bi-directional flow of energy between a dwelling and a vehicle. In other words, the house can fuel the car and the car can fuel the house. What’s more, ORNL used 3D printing technology to build the dwelling and the vehicle, before successfully trialing the new energy system.

“In the AMIE demonstration project, we are trying to illustrate what our future might look like if we shared our energy streams for buildings and transportation, using additive manufacturing as a tool to drive rapid innovation,” ORNL’s Roderick Jackson, who led the AMIE demonstration project, told Gizmag. “The challenges we face can’t wait for the innovation cycles that currently exist for our buildings and vehicles energy ecosystem. These challenges include electricity outages caused by extreme weather events, energy poverty around the globe, and intermittent renewable generation.”

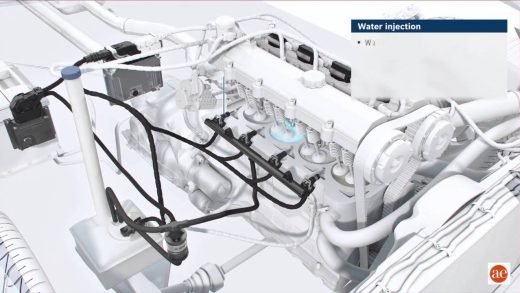

AMIE boasts the world’s very first working level 2 (6.6 kW) bi-directional power system. The building is fitted with a flexible 3.2 kW solar photovoltaic system, which is then paired with electric vehicle batteries, providing renewable power generation and storage. Energy can flow in either direction between the house and the vehicle via a wireless transfer system. This also means the vehicle can power the house when the sun has gone down or during cloudy periods.

“In one-direction, AMIE can charge the car battery and in the other direction, the car can power AMIE,” said Jackson. “The efficiency of the bidirectional wireless power transfer (BWPT) system is roughly around 85 percent. BWPT uses a resonant technology that allows higher efficiencies through larger gaps.”

ORNL worked alongside architectural studio Skidmore, Owings & Merrill to construct the 210 sq ft (19.5 sq m) building. The single-room structure was built using 3D-printed parts and features curved lines and cost effective vacuum insulated panels. The home is equipped with a micro-kitchen concept, developed by GE FirstBuild, and the rooftop photovoltaic system is paired with batteries from a previously used Fiat 500e.

“One of the interesting energy saving features is novel modified atmosphere insulation (MAI) panels developed by NanoPore that are about seven times more energy efficient than traditional wall insulation,” revealed Jackson.

Carbon fiber-reinforced ABS plastic composite material was used to print approximately 80 percent of the house components and 30 percent of the vehicle’s. The fact that the team could build the structure using 3D technology meant design elements could be tested and trialed without losing time or momentum. It also meant they could create curved shapes and perfectly fitting bespoke elements without the limitations of traditional building techniques.

“Our ability to test design form and fit at scale and in real time enabled an ‘innovation on the fly’ process that could revolutionize how we approach building construction and design,” ORNL’s Director of Energy and Transportation Science Division, Johney Green Jr, told Gizmag.

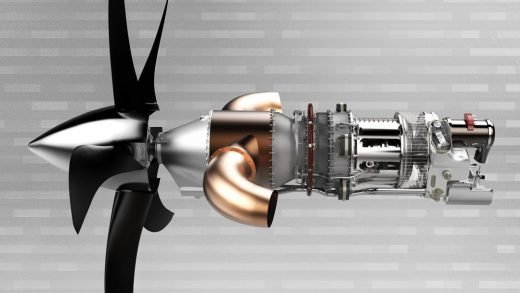

The 3D-printed utility vehicle features an electric hybrid power-train, which makes use of natural gas to extend its range. Thanks to creating the vehicle with 3D-printed components, the appearance of the vehicle can be modified with new body parts as desired.

Although the weight of the vehicle is currently close to 4,010 lb (1,819 kg), additional research will go into developing a lightweight version. ORNL is also hoping to trial external combustion engines such as the Stirling engine; high efficiency internal combustion engines with bio-fuels, hydrogen fuel cells and advanced energy storage units, such as flow batteries and consumable batteries.

“The energy generator used in the current configuration is a very small internal combustion engine natural gas generator,” said Green. “This small 5.5 kW engine/generator is an example of the extreme downsizing possible with range extended electric vehicle configurations. In addition to range extension for the printed utility vehicle, the engine/generator is ideally sized for providing power to small buildings such as the printed AMIE house.”

It should also be noted that the current prototype was not designed around optimum speed or performance, but more to demonstrate the capabilities of AMIE.

“The printed utility vehicle is currently configured with a 14 kWh battery, which with the current weight allows an all-electric range of 35 miles for city driving and a top speed suited for highway use (~60 mph),” continued Green. “We could configure the vehicle to have different performance characteristics. The range of the vehicle depends upon how much fuel is carried on board and the speed of the vehicle depends upon the power-train configuration.”

ORNL is currently considering the option of making the plans open source and there is already talk of an AMIE 2.0, incorporating improvements and lessons learnt from AMIE 1.0.

“We have not finalized any plans to put the design files in the public domain, but that is something worth considering,” said Jackson. “We hope that this project inspires others to ask ‘what if’ and use technology to drive innovation.”

The video below illustrates the ideas and technology behind ORNL’s AMIE demonstration.

Source: Oak Ridge National , Oak Ridge National Laboratory

Photo/video source: Oak Ridge National

Recent Comments